Accelerating Sustainability

Sustainability has shifted from being an optional strategy to a core priority for businesses worldwide. As climate change awareness grows, regulatory standards tighten, and consumers lean toward eco-friendly products, manufacturers are under increasing pressure to minimize their environmental footprint while maintaining efficiency. Production Schedulers in industrial manufacturing are uniquely positioned to play a crucial role in this transformation.

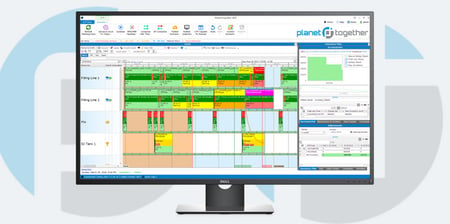

Integrating Advanced Planning and Scheduling (APS) systems like PlanetTogether with leading ERP systems—such as SAP, Oracle, Microsoft, Kinaxis, or Aveva—empowers Production Schedulers to drive sustainability. This integration can improve resource efficiency, reduce waste, optimize energy consumption, and support more sustainable decision-making at every step of the production cycle.

The Role of a Production Scheduler in Sustainable Manufacturing

Sustainable manufacturing is an approach that prioritizes reducing environmental impact across the production lifecycle, from raw materials sourcing to finished product delivery. As a Production Scheduler, your primary responsibilities—streamlining workflows, balancing resource loads, reducing downtime, and improving efficiency—align closely with the pillars of sustainability.

By adopting a sustainable mindset, you can help your facility achieve key sustainability goals, including:

Reducing waste: Minimizing overproduction and inventory can lead to significant waste reduction.

Optimizing resource usage: Efficiently scheduling resources like materials, labor, and machinery can reduce energy consumption and lower emissions.

Increasing operational transparency: Real-time insights into production stages support the identification and improvement of inefficient or environmentally harmful practices.

A well-integrated APS and ERP system provides the tools you need to manage these goals effectively. The integration of PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva offers a robust solution for sustainable manufacturing by allowing more accurate planning, monitoring, and scheduling decisions.

![]()

How PlanetTogether and ERP Integration Fuels Sustainability

APS systems like PlanetTogether are purpose-built for optimizing production schedules, but when combined with ERP platforms, their sustainability potential is significantly amplified. Let’s explore how this integration supports sustainable manufacturing efforts:

Enhanced Visibility and Data-Driven Decisions

With APS-ERP integration, you gain access to real-time data and analytics across the production lifecycle. PlanetTogether offers a comprehensive view of production resources, machine capacity, labor availability, and inventory status, while the ERP platform manages financials, material procurement, and sales forecasting.

For instance, when PlanetTogether is integrated with SAP or Oracle, you can instantly visualize production bottlenecks or resource overuse, enabling you to make more sustainable scheduling adjustments. This level of insight prevents over-scheduling, reduces unnecessary machine run times, and minimizes wasteful inventory buildup.

Efficient Resource Utilization

Effective production scheduling means more than just organizing tasks; it’s about managing resources sustainably. By integrating PlanetTogether with Microsoft or Kinaxis, you can develop schedules that optimize machinery utilization, minimize idle times, and reduce energy consumption.

Real-time feedback from your ERP system informs the APS about available raw materials and parts. As a Production Scheduler, you can adjust schedules based on current inventory levels, ensuring that resources aren’t overused or underutilized.

Minimizing Overproduction and Excess Inventory

Overproduction is one of the primary contributors to waste in industrial manufacturing. Through PlanetTogether’s forecasting capabilities combined with demand data from Aveva or other ERP systems, you can closely align production with demand.

This alignment helps prevent surplus inventory, which not only reduces waste but also lowers energy consumption associated with storage. Efficient scheduling based on real-time demand data results in less scrap, fewer excess materials, and reduced resource expenditure—all of which support sustainability.

Reducing Energy Consumption

PlanetTogether’s APS system allows you to build energy-efficient schedules by analyzing machine energy consumption patterns and adjusting production runs accordingly. Integrating this capability with ERP solutions like SAP or Oracle enables you to consider machine maintenance schedules, energy-efficient work orders, and peak energy hours.

By concentrating energy-intensive processes during off-peak hours or spacing them out to prevent high energy demand, you can significantly reduce your facility’s overall energy usage and contribute to a greener manufacturing process.

Real-Time Adaptability to Reduce Waste

One of the standout advantages of integrating PlanetTogether with an ERP is real-time adaptability. When unexpected events—such as raw material delays or machine breakdowns—occur, PlanetTogether’s APS can immediately adapt the schedule and minimize disruptions.

Integration with systems like Kinaxis, known for supply chain agility, helps prevent last-minute scrambles that often lead to rushed production and increased waste. By adjusting schedules promptly, you can avoid unnecessary rework, eliminate wastage, and keep production flowing sustainably.

Predictive Maintenance to Extend Equipment Life

Sustainability isn’t limited to materials and energy; it also includes equipment longevity. Through APS and ERP integration, predictive maintenance data from ERP systems can inform PlanetTogether of when machines need servicing, allowing you to plan preventive maintenance schedules.

A predictive maintenance strategy prolongs equipment life, reduces breakdowns, and decreases the need for new machinery, all of which contribute to a more sustainable operation. With systems like SAP or Oracle providing predictive analytics, you can incorporate maintenance schedules that align with production, avoiding disruptions and improving resource efficiency.

Implementing PlanetTogether-ERP Integration for Sustainable Manufacturing

If you’re considering the integration of PlanetTogether with an ERP like SAP, Oracle, Microsoft, Kinaxis, or Aveva to support sustainable manufacturing, here’s a step-by-step guide to implementing this solution:

Assess Your Sustainability Goals

Define clear, measurable sustainability objectives for your facility. These may include reducing energy usage, minimizing waste, or decreasing machine idle time.

Evaluate Your Existing ERP System’s Capabilities

Determine if your current ERP system is compatible with PlanetTogether’s APS. Each ERP system has unique capabilities, so ensure that it can support real-time data transfer, predictive analytics, and maintenance scheduling.

Set Up Data Synchronization and Real-Time Integration

Work with IT teams to synchronize data between PlanetTogether and your ERP system. This integration should allow for real-time updates, ensuring your scheduling decisions are informed by the latest production and supply chain data.

Pilot Test the Integration

Before rolling out the integration facility-wide, conduct a pilot test to measure the system’s effectiveness in achieving sustainability goals. Assess if the integration helps you reduce energy use, cut down on waste, or improve production efficiency.

Train Your Production Scheduling Team

Ensure that your team understands how to use the integrated APS and ERP system to support sustainability objectives. Training should cover using data analytics, predictive maintenance features, and adapting schedules for optimal resource use.

Monitor and Refine

Sustainable manufacturing is a continuous process. Regularly monitor the system’s performance, track progress toward sustainability goals, and refine schedules based on data insights. By consistently evaluating and adjusting, you can ensure that your facility stays on track for continuous improvement.

The future of industrial manufacturing lies in smart, integrated systems that prioritize both productivity and sustainability. As a Production Scheduler, embracing tools like PlanetTogether’s APS integrated with ERP platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva positions you at the forefront of this transition.

This integration doesn’t just improve production scheduling—it transforms it into a strategic tool for sustainable operations. With a powerful combination of real-time data, predictive capabilities, and intelligent scheduling, you can turn sustainability from a complex challenge into an achievable objective.

By leveraging technology, integrating systems, and focusing on sustainability, you’re not only contributing to the planet’s well-being but also driving long-term profitability and resilience for your organization. Sustainable manufacturing is here to stay, and with the right tools, Production Schedulers like you have the power to lead the charge.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether and integrated scheduling solutions can help you achieve your sustainability goals and drive success in your industry.

Topics: Industrial Manufacturing, PlanetTogether Software, Integrating PlanetTogether, Efficient Resource Utilization, Enhanced Visibility and Data-Driven Decisions, Minimizing Overproduction and Excess Inventory, Reducing Energy Consumption, Real-Time Adaptability to Reduce Waste, Predictive Maintenance to Extend Equipment Life

LEAVE A COMMENT