Accelerating Success: How Pharmaceutical Plant Managers Can Reduce Production Times and Costs with Integrated Planning Tools

In pharmaceutical manufacturing, time and cost are two sides of the same coin. Delays can not only jeopardize supply chain continuity but also hinder patient access to critical medications. Simultaneously, soaring operational expenses can undermine profitability and regulatory compliance. For Plant Managers, balancing these challenges requires more than operational vigilance—it demands intelligent, integrated systems that enable agility, precision, and cost-efficiency.

This is where advanced planning and scheduling (APS) solutions like PlanetTogether, especially when integrated with enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, make a transformative impact. By unifying real-time production data, inventory management, and resource allocation within a single digital ecosystem, these integrations empower plant managers to optimize workflows, reduce production cycles, and significantly cut operational costs.

This blog explores how integrated APS solutions can become a cornerstone for pharmaceutical plant managers looking to gain control over time-sensitive production while achieving cost-effectiveness and compliance.

The High Cost of Delays in Pharma Manufacturing

Pharmaceutical production is inherently complex—marked by stringent regulations, variable batch sizes, fluctuating demand, and precise formulations. Traditional planning tools or spreadsheets fall short in environments where agility is non-negotiable.

Some of the most pressing challenges include:

Lengthy batch production cycles due to inefficient scheduling

Underutilization or overbooking of equipment

Inventory misalignment with demand forecasts

Unplanned downtimes and resource conflicts

Manual planning processes prone to human error

Each inefficiency not only increases costs but also stretches lead times and puts compliance at risk.

Integrated APS: A Strategic Solution

PlanetTogether APS helps pharmaceutical manufacturers plan, schedule, and monitor production with unmatched visibility and control. However, its true power is realized when integrated with ERP and MES systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva. This integration breaks down data silos and ensures that every stakeholder—from procurement to QA—has access to synchronized, accurate, and actionable information.

Benefits of Integration for Plant Managers

Real-Time Synchronization

Integrated systems ensure that material availability, equipment status, and personnel capacity are reflected instantly in the production schedule.

For example, when SAP inventory levels are updated, PlanetTogether can automatically adjust schedules to avoid raw material shortages.

Streamlined Batch Scheduling

PlanetTogether allows precise batch scheduling with constraints around changeovers, cleaning validation, and allergen control—all synced with ERP master data.

Integration with systems like Microsoft Dynamics or Oracle helps Plant Managers reduce unnecessary idle time between batches.

Dynamic Rescheduling Capabilities

When unforeseen events occur—equipment failure, late raw material delivery, or personnel absence—APS tools can reschedule production automatically to minimize disruption.

Kinaxis integration supports rapid supply chain reconfiguration, keeping production aligned with demand.

Enhanced Resource Utilization

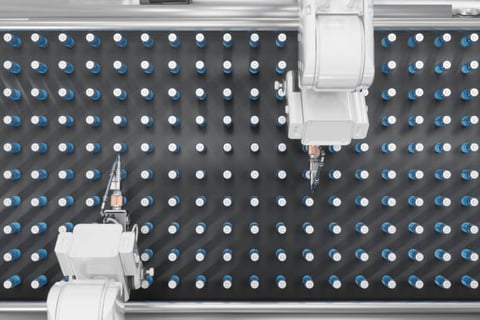

Integrated insights help in balancing workloads across machines and shifts, ensuring no asset is underused or overburdened.

Aveva’s real-time equipment monitoring, when paired with PlanetTogether, provides granular insights into asset performance.

Predictive Maintenance Integration

By linking predictive maintenance modules from Aveva or Microsoft with scheduling tools, downtime can be scheduled intelligently rather than reactively, minimizing production interruptions.

Key Strategies to Reduce Production Times

Optimize Changeovers and Cleaning Cycles

In pharmaceutical manufacturing, changeovers and cleaning validations can consume substantial time. Through integrated scheduling, PlanetTogether minimizes transitions between incompatible products, reducing cleaning needs and saving hours of downtime.

Integration Example:

With Oracle ERP providing product compatibility data, PlanetTogether can auto-sequence batches to group similar products together, slashing the time lost in changeovers.

Enable Concurrent Processing and Parallel Scheduling

Many pharma operations involve concurrent activities—such as granulation, coating, and packaging. Integrated APS solutions allow plant managers to schedule these in parallel, rather than sequentially, based on equipment and personnel availability.

Result: Reduced total cycle time and faster product release to market.

Align Scheduling with QA Availability

Often, production is completed, but final release is delayed due to QA resource constraints. Integration with systems managing QA schedules and resources enables PlanetTogether to align batch completion with QA review windows, speeding up time to market.

Key Strategies to Reduce Costs

Reduce Overtime and Expedite Costs

By accurately forecasting workloads and synchronizing with ERP labor and procurement data, plant managers can avoid last-minute rush orders, expedite shipping, or unplanned overtime—significant cost drivers in pharma.

Optimize Inventory Holding

Holding too much inventory ties up capital and increases storage and expiry risks. Integration with Kinaxis or SAP helps align production with just-in-time principles, using real-time demand forecasts to drive batch production.

Avoid Costly Compliance Violations

Non-compliance can lead to product recalls, fines, or production halts. Integrated systems ensure that schedules reflect all compliance requirements—from environmental monitoring to validation documentation—helping avoid these expensive disruptions.

Leading the Charge Toward Smarter, Leaner Manufacturing

Pharmaceutical Plant Managers today are tasked with delivering high-quality products faster and at lower costs—without compromising compliance. This balance can only be achieved through intelligent tools that bring clarity, speed, and agility to the production floor.

By integrating PlanetTogether APS with ERP/MES platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, plant managers can gain complete visibility into operations, streamline production timelines, and significantly reduce waste and costs.

It's not just about planning better—it's about manufacturing smarter. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Enhanced Resource Utilization-, Dynamic Rescheduling Capabilities, Real-Time Synchronization, Pharmaceutical Manufacturing, Streamlined Batch Scheduling, Predictive Maintenance Integration

LEAVE A COMMENT