Precision Meets Flexibility: Adaptive Manufacturing Powered by PlanetTogether and ERP Integration

Empower medical manufacturing with adaptive planning. Discover how PlanetTogether + ERP integration helps Production Planners boost agility and...

Learn key strategies & tools for production planners to accelerate change management & reduce time to market, including PlanetTogether integration with ERP & SCM.

In the industrial manufacturing landscape, the ability to adapt to change quickly and efficiently is essential to success. Production planners play a crucial role in orchestrating the flow of materials, resources, and information to ensure products are delivered to market on time and at optimal cost. However, with the complexity of global supply chains and increasing customer demands, traditional methods of planning and execution are no longer sufficient.

To stay competitive, production planners must embrace best practices and strategies that accelerate change management and reduce time to market.

In this blog, we'll explore key tactics and tools, including integration between PlanetTogether and leading ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva, to empower production planners in driving efficiency and agility.

Change is inevitable in manufacturing, whether it's due to shifts in customer demand, supply chain disruptions, or internal process improvements. However, managing change effectively is often easier said than done. Without proper planning and execution, changes can lead to production delays, increased costs, and unhappy customers.

Production planners must recognize the significance of change management and its impact on time to market. By establishing robust change management processes, organizations can mitigate risks and capitalize on opportunities for innovation and improvement.

![]()

One of the cornerstones of effective production planning is the adoption of advanced planning and scheduling (APS) solutions like PlanetTogether. These software tools use algorithms and optimization techniques to generate accurate production schedules based on various constraints and objectives.

Integration between APS solutions and ERP, SCM, and MES systems is critical for seamless data exchange and real-time visibility across the manufacturing ecosystem. By integrating PlanetTogether with platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, or Aveva, production planners can access up-to-date information on inventory levels, order status, and resource availability, enabling better decision-making and faster response to changes.

Change management is not solely the responsibility of the production planning department. It requires collaboration and alignment across different functions within the organization, including sales, procurement, operations, and engineering.

By fostering a culture of collaboration and communication, production planners can gain valuable insights into market trends, customer preferences, and supply chain dynamics. Cross-functional teams can work together to identify potential risks and opportunities, develop contingency plans, and execute change initiatives more effectively.

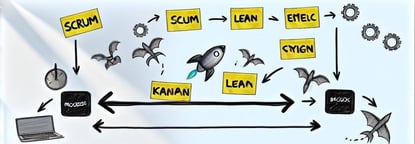

In today's dynamic business environment, traditional waterfall approaches to project management are giving way to more agile methodologies. Agile principles emphasize adaptability, iterative development, and continuous improvement, making them well-suited for managing change in manufacturing.

Production planners can leverage agile frameworks such as Scrum or Kanban to break down complex projects into manageable tasks, prioritize work based on value and urgency, and respond quickly to changing requirements. By embracing agile methodologies, organizations can reduce time to market, increase productivity, and enhance customer satisfaction.

Effective change management requires not only the right tools and processes but also skilled and empowered employees. Production planners should invest in training and development programs to equip their teams with the knowledge and skills needed to navigate change successfully.

Training programs can cover a range of topics, including APS software proficiency, lean manufacturing principles, problem-solving techniques, and interpersonal skills. By investing in employee development, organizations can build a more resilient and adaptable workforce capable of driving continuous improvement and innovation.

Finally, to ensure the effectiveness of change management initiatives, production planners must establish key performance indicators (KPIs) and metrics to monitor progress and measure success. These metrics may include cycle time, on-time delivery, inventory turnover, and customer satisfaction.

By regularly tracking performance metrics, production planners can identify areas for improvement, assess the impact of change management initiatives, and make data-driven decisions to drive continuous improvement.

Accelerating change management and reducing time to market are critical imperatives for production planners in industrial manufacturing facilities. By embracing best practices and strategies such as leveraging advanced planning and scheduling solutions, establishing cross-functional collaboration, implementing agile methodologies, investing in employee training and development, and monitoring performance, organizations can enhance their agility, responsiveness, and competitiveness in today's dynamic marketplace.

Integration between PlanetTogether and leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, or Aveva plays a pivotal role in enabling seamless data exchange and real-time visibility, empowering production planners to make informed decisions and drive operational excellence.

By embracing these best practices and leveraging the right tools and technologies, production planners can navigate change effectively and deliver superior value to customers while accelerating time to market.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Empower medical manufacturing with adaptive planning. Discover how PlanetTogether + ERP integration helps Production Planners boost agility and...

Learn how pharmaceutical purchasing managers can master multi-plant capacity planning with integrated tools like PlanetTogether and ERP systems.

Learn how AI and PlanetTogether, integrated with ERP systems, empower pharmaceutical manufacturers to manage last-minute changes efficiently.

Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of today’s industry.